Nicolás Correa S.A., founded in 1947, is the parent company of the Nicolás Correa Group.

With over 900 bridge type machines, 1.000 floor type machines and 3.500 bed type machines installed all over the world, offers milling solutions designed for the most demanding production environments, such as the power generation, automotive, aerospace and railway industries.

Thousands of customers throughout the world continue to place their trust in our range of milling machines, manufactured in our Burgos plants. Nicolás Correa currently exports around 90% of its production to over 20 different countries. To this end, it has a broad network of distributors and trading subsidiaries which ensure direct, personal contact with customers.

Belonging to the group provides NICOLÁS CORREA with access to top-quality critical supplies and enables the company to satisfy all its customers' flexibility requirements.

NICOLÁS CORREA offers the widest range of milling solutions on the market, including bed machines, gantry machines, floor type machines and machines with a T-shaped configuration.

The entire range is designed and manufactured in Spain. Nicolás Correa, S.A. has been listed on the Madrid Stock Exchange since 1989. To guarantee a high-quality service to our customers, we have an extensive international commercial and technical service network, and are present either directly or indirectly through our agents in the majority of the world's countries.

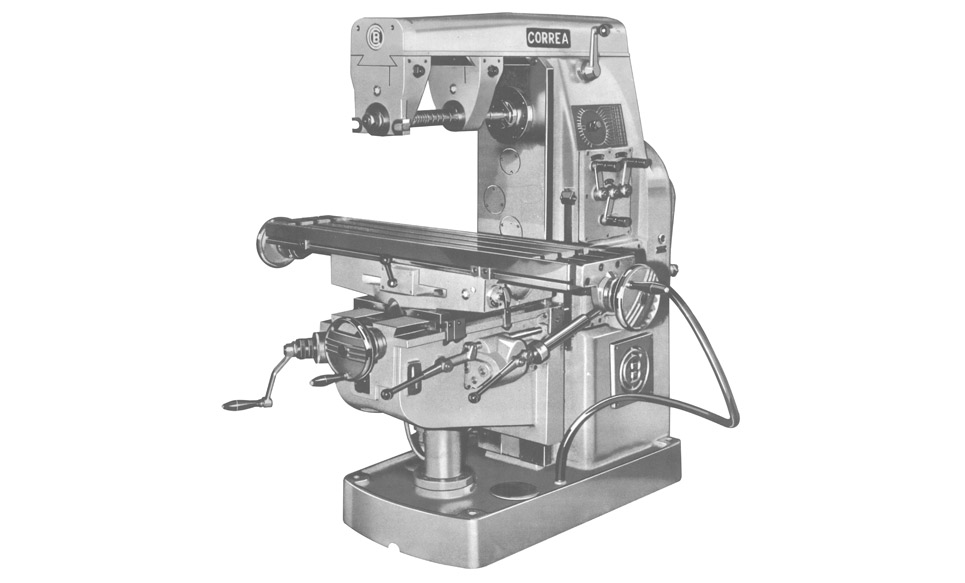

The first Correa milling machines were manufactured with a staff of just twelve workers.

Correa milling machines in the F2 range began to incorporate electromagnetic clutches which enabled them to increase their roughing capacity, while maintaining the same level of precision.

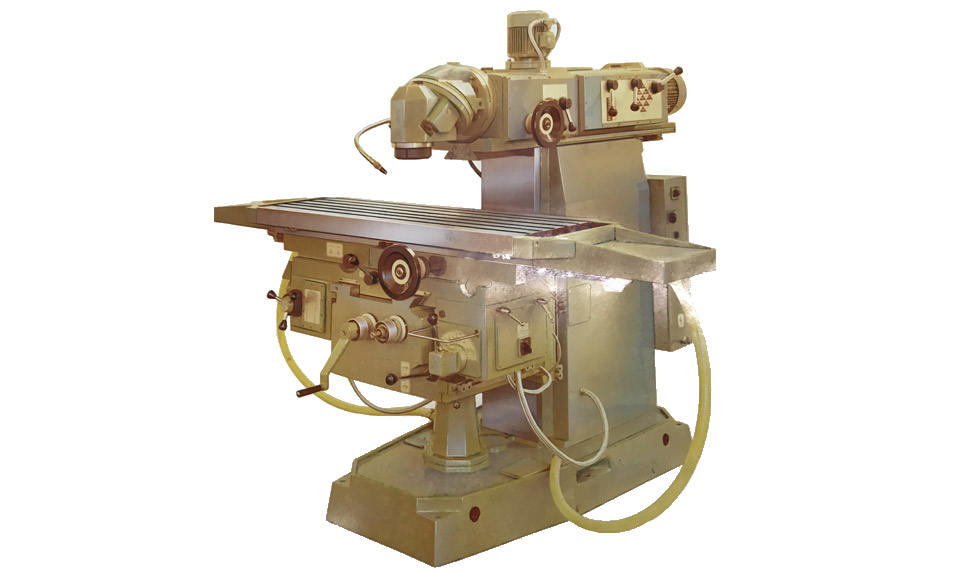

Nicolás Correa began to manufacture larger milling machines, with squared and cubed cycles that rendered them more competitive at an international level.

At the end of the 1970s, the structure of the milling machines was modified, and they started to incorporate beds in order to offer greater robustness. For the first time, Nicolás Correa began to use 'box in box' technology in the design of its milling machines.

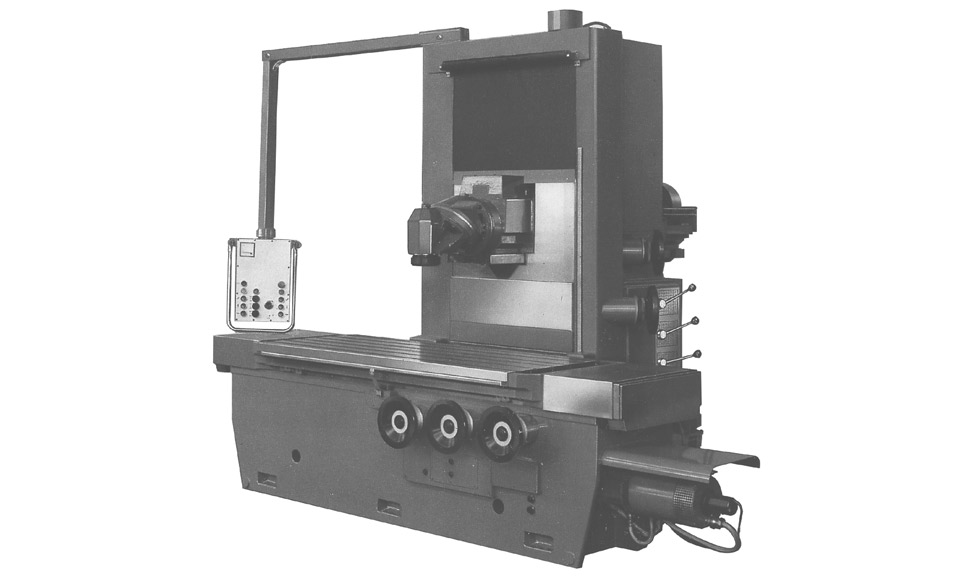

The Correa A-30 milling machine was a major innovation, since it incorporated a numerical control. Moreover, thanks to its larger size, it was able to machine larger parts. During this period, specifically in 1989, Nicolás Correa was floated on the Madrid Stock Exchange.

Nicolás Correa launched its first floor type machine. The L-30 could machine large parts as well as work in pendulum mode.

The FP range machines represented a completely new type of bridge type machine which enabled Nicolás Correa to become the leading manufacturer of bridge type milling machines in Europe.

Nicolás Correa has developed its range of state-of-the-art floor type milling machines by applying 'box in box' technology and incorporating the most advanced ram drop correction system currently on the market.

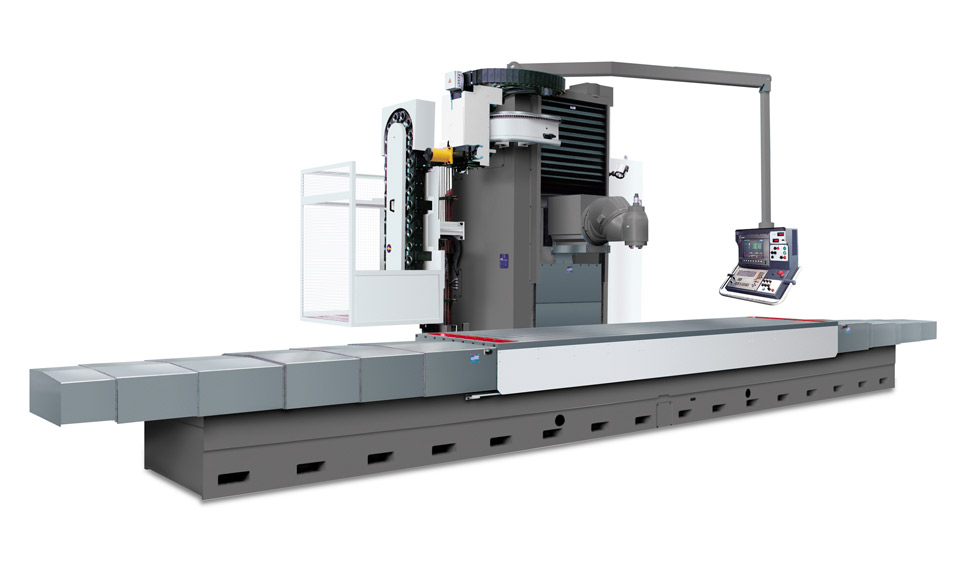

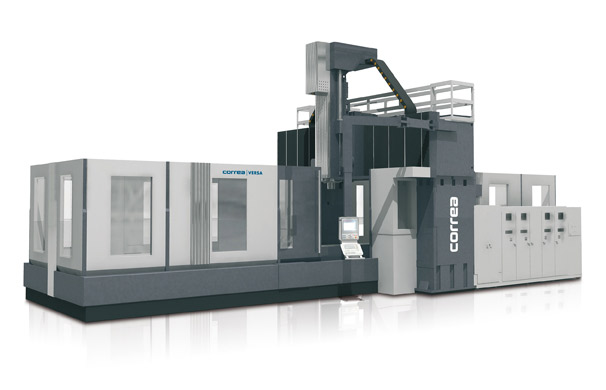

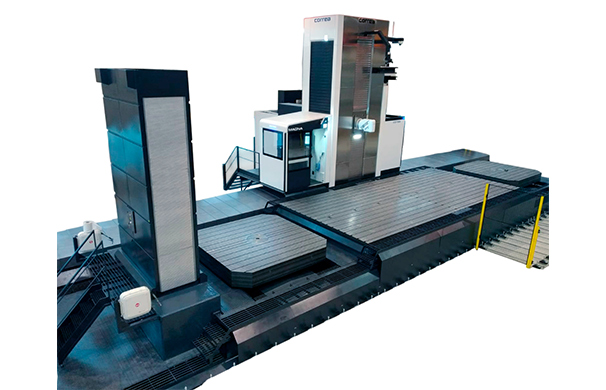

Nicolás Correa launched the Verxa family onto the market. By applying only the very latest technology, Nicolás Correa now manufactures a range of the largest bridge type machines in its history.

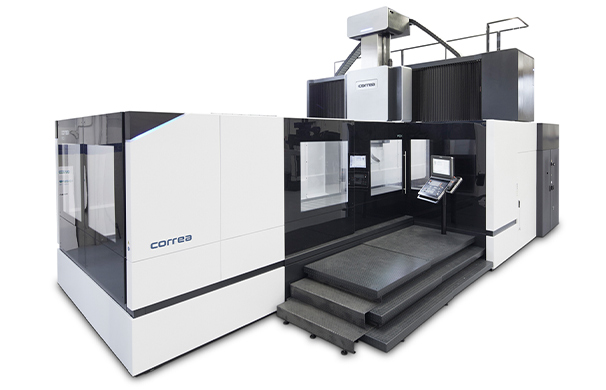

Nicolás Correa launched the Fox family onto the market. This family combines all the knowledge and experience accumulated by the company over the last 20 years in the field of bridge type machine manufacture. The Fox range incorporates a unique series of systems for controlling the temperature in the vertical axis.

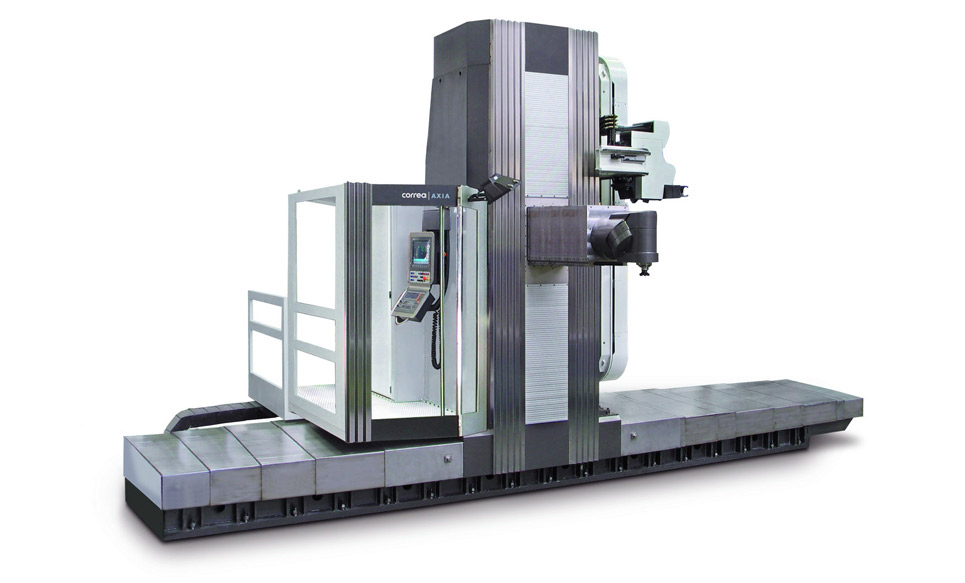

Nicolás Correa develops the first multitasking milling-turning machine. It does so thanks to a key contract with the French multinational EDF where Nicolás Correa sells three multifunction milling machines model HVM and Axia (2 units) respectively in 3 different production plants in France.

Nicolás Correa starts a new project to update the industrial image of the machines, improving their functional and ergonomic aspects. The new industrial image seeks to reinforce the attributes of the Correa brand, positioning it at the top of its segment in terms of technology and quality.

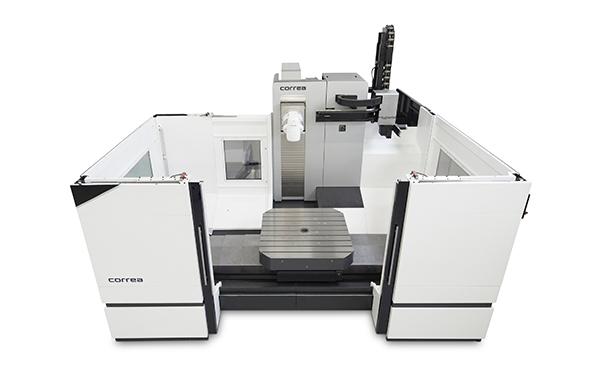

Nicolás Correa - Hypatia launches a new family based on the NORMA model, but with a rotary table integrated in the X axis. The flexibility of having a machine capable of working in 4+2 axes, allows to improve the positioning in many sectors.

Nicolás Correa launches a new family of high-speed Top Gantry machines for working cubes somewhat smaller than the ORIX. It is the fastest machine manufactured by Nicolás Correa to date with maximum feed rates of up to 60 m/min.

Nicolás Correa develops the UDX head, where he applies a unique technology in the market. It is the first time in history that someone manufactures a mechanical transmission head capable of turning at 10,000 rpm. This head, which can be offered on the entire range of Correa machines, offers unique features and improves market psitioning and in sectors such as the automotive industry.

Nicolás Correa develops a complete family of rotary tables with and without linear axis, thus consolidating its vertical integration strategy initiated years ago.

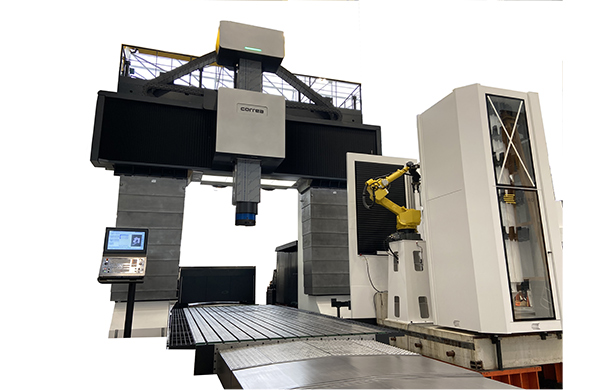

Nicolás Correa installs its first machine with an automatic robot-type tool changer in Burgos. These new tool changers allow a large number of tools to be used, giving the system unprecedented flexibility to improve the automation of machining processes.

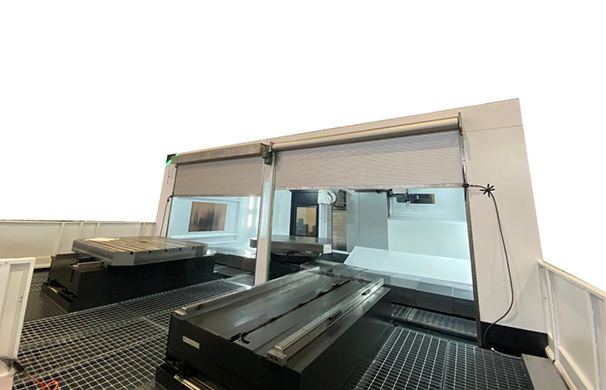

Nicolás Correa designs and implements the first automatic pallet changing system in its Norma MG model. These systems provide the machine with much greater autonomy, allowing parts to be loaded and unloaded automatically.

Nicolás Correa designs and implements automatic pallet changing systems in different families of machines, both horizontal ram and vertical ram, also incorporating pallets for milling and turning.