Technical specifications

| 40 | 55 | 70 | 85 | 100 | 115 | 130 | ||

|---|---|---|---|---|---|---|---|---|

| Table width | ||||||||

| Surface | mm | 1.750 2.500 3.000 3.500 | 1.750 2.500 3.000 3.500 | 1.750 2.500 3.000 3.500 | 1.750 2.500 3.000 3.500 | 1.750 2.500 3.000 3.500 | 1.750 2.500 3.000 3.500 | 1.750 2.500 3.000 3.500 |

| Maximum load on the table | Kg/m2 | 10000 - 15000 | ||||||

| Travels | ||||||||

| Longitudinal | X mm | 4.000 | 5.500 | 7.000 | 8.500 | 10.000 | 11.500 | 13.000 |

| Transversal | Y mm | 3.000 - 3.750 - 4.250 - 5.000 / DBC: 2.250 - 3.000 - 3.500 - 4.250 | ||||||

| Vertical | Z mm | 1.500 / 1.750 | ||||||

| Vertical | W mm | 1.000 / 2.000 | ||||||

| Feeds | ||||||||

| Maximum | X m/min | 25 | ||||||

| Y m/min | 30 | |||||||

| Z m/min | 30 | |||||||

| Spindle specifications | ||||||||

| Taper | ISO-50 Big Plus / HSK-100 | |||||||

| Spindle speed | rpm | 6.000 / 10.000 | ||||||

| Maximum power | kW | 37 / 52 / 42 | ||||||

| Maximum torque | Nm | 1.298 / 1.375 / 620 | ||||||

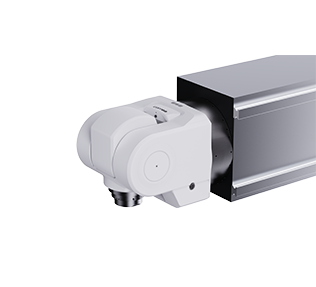

Heads

UAD Technology

Universal and orthogonal indexing milling heads unique in the market. Patented technology allowing rotation every 0,02º.

5 axes Technology.

2 axes contouring head "Twist" type with built in electrospindle or spindle geared transmission.

Are you interested in our heads?

Standard and optional equipment

Standard equipment

- Automatic Universal Head

- Numerical control Heidenhain or Siemens (Operate HMI)

- Portable handwheel

- Air-conditioned electrical cabinet

- Linear guides in the X, Y axes

- Friction guide at Z axis

- Lamp in the working area

- Hydraulic and cooling group

- Absolute Heidenhain measurement rules in all axes

- Exterior coolant with adjustable lance nozzles

- Internal and external air flow

- Guarding

- Tele-service

- VIXION 4.0

Optional equipment

- Other heads

- Automatic head-changer

- Probes of measurement, tools and parts

- Automatic charger for 30, 40, 60, 120 tools

- Pick up station for 6, 8, 12 tools

- Air/Coolant cleaning gun

- Self cleaning filter

- Rotary tables

- Chip conveyors

- Perimeter fence

- Full guarding (Only in some models)

- Coolant through the spindle

- Zero-point systems for rapid part change